The Impact of Terminal Torque on Circuit Breaker Overheating

28th feb 2026

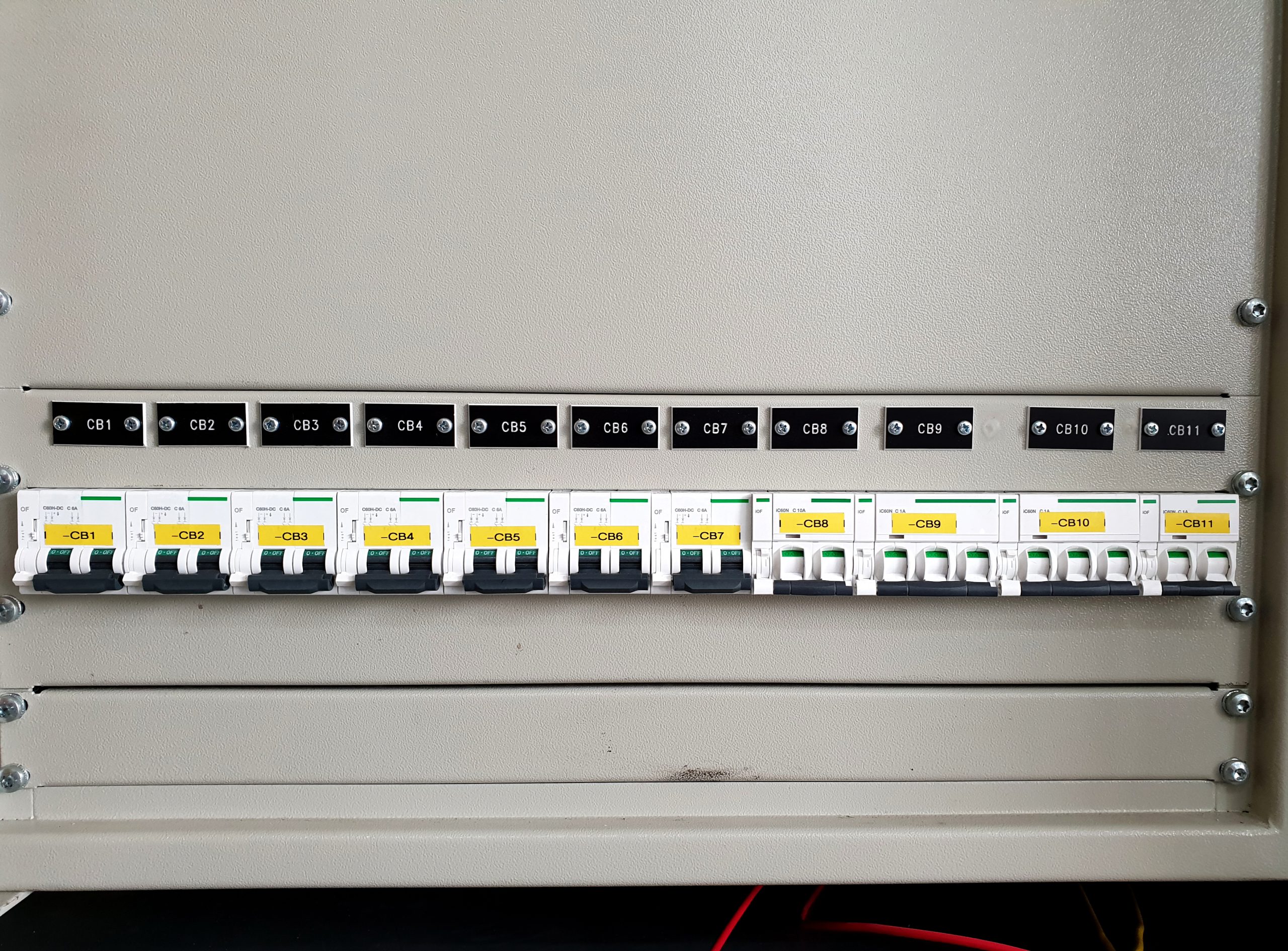

In the field of electrical engineering, safety is determined by a secure connection and the circuit breaker. During electrical installations, terminal torque is often overlooked. This is defined as the “perfect tightness” of rotational force applied to the terminal screws. When the necessary rotational force is not properly applied, your circuit breaker is compromised. According to Joule’s Law, resistance generates heat and increases with the square of the current and the resistance of the connection. This is shown by the formula P = I2R. To prevent rapid overheating, the correct terminal torque should be applied to a circuit breaker. Real-World Scenarios and Operational Risks In industrial and commercial electrical systems, engineers may impose safety measures. However, these may contradict certain site conditions. There may also be instances where circuit breaker failures are caused by human factors. Understanding how proper terminal torque affects the circuit breaker is essential for electrical fire prevention. Below are some real-world scenarios demonstrating the operational risks caused by incorrect terminal torque conditions: Loose Wiring & Thermal Cycling In busy factories, the vibrations coming from heavy machinery may cause tightened terminals to loosen. In electricity, when the lug doesn’t make full contact with the terminal, this creates electrical resistance. As resistance increases, so does the temperature. This results in a dangerous loop called “thermal cycling.” One of the solutions to thermal cycling is to ensure that the initial “preload” on a bolt or screw is correct. Use a calibrated torque wrench and follow the manufacturer’s specific N · m (Newton-meter) or in.lb […]

Lees meer : +86-139 0587 7291

: +86-139 0587 7291 Engels

Engels Spaans

Spaans Russisch

Russisch Frans

Frans Arabisch

Arabisch Braziliaans Portugees

Braziliaans Portugees Oekraïens

Oekraïens Turks

Turks Pools

Pools Nederlands

Nederlands Italiaans

Italiaans Indonesisch

Indonesisch Hindi

Hindi اردو

اردو sjoemelen

sjoemelen अर्नुहोस्थार्नुहोस्

अर्नुहोस्थार्नुहोस् ไทย

ไทย Molukken

Molukken فارسی

فارسی Sjiek

Sjiek Edelstenen

Edelstenen