Udhëzues hap pas hapi: Si të testoni një kontaktor

Tabela e Përmbajtjes

Ndrysho

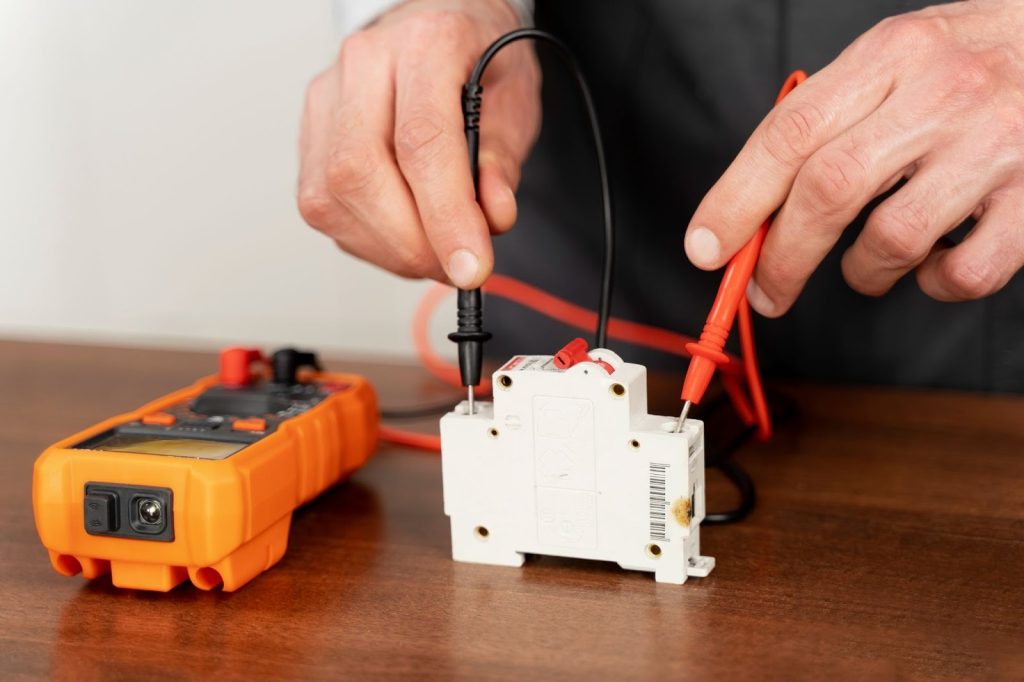

Testing a contactor is the safest way to know if it is working correctly or if it needs replacement. The bottom line: you test a contactor by checking its coil resistance, contact resistance, and overall operation using a multimeter. In this guide, you’ll learn exactly how to test a contactor step by step, including safety checks and troubleshooting tips. Whether you’re a beginner or refreshing your knowledge, this article will give you the confidence to work safely with electrical equipment.

What Is a Contactor?

A kontaktor is an electrically controlled switch used in circuits that handle high current, such as motors, pumps, and HVAC systems.

Three key takeaways:

- It uses a small control voltage to switch a larger load current.

- It contains a coil, contacts, and a moving armature.

- It is built for frequent switching, unlike a regular switch.

Why Learn How to Test a Contactor?

Contactors wear out over time due to heat, arcing, and mechanical stress. If not checked, a faulty contactor can cause equipment downtime, overheating, or even electrical hazards. Learning how to test a contactor with a multimeter helps you:

- Prevent unexpected equipment failure.

- Improve electrical safety in homes and industries.

- Save costs by spotting faults early.

Safety First Before Testing

Working with contactors means working with live electrical systems. Before learning how to test an AC contactor, follow these precautions:

- Disconnect Power: Turn off the circuit breaker and make sure no power is flowing.

- Lockout/Tagout: Use proper lockout devices to prevent accidental re-energizing.

- Wear PPE: Always use insulated gloves and safety glasses.

- Have a Partner: For high-voltage tests, work with another qualified person nearby.

Tools You Need

To test a contactor properly, gather:

- Digital multimeter (for resistance and continuity)

- Insulated screwdrivers

- Voltage tester

- Wire strippers

- Contact cleaner (optional for maintenance)

Step 1: Visual Inspection

Before using a tool, inspect the contactor for:

- Burn marks, discoloration, or melting.

- Loose or corroded wiring.

- Pitted or worn contact surfaces.

If you see major physical damage, the contactor should be replaced immediately.

Step 2: Coil Resistance Test

The contactor coil is what energizes the device. Testing the contactor coil resistance shows whether the coil is healthy.

- Disconnect the coil from the circuit.

- Set your multimeter to the ohms (Ω) scale.

- Place the probes on the coil terminals.

- Compare the reading to the manufacturer’s specs.

A very high or infinite resistance usually means a burned-out coil. Very low resistance may mean a short circuit.

Step 3: Contact Resistance Test

Next, check the main contacts to ensure they close properly.

- Make sure the contactor is in the “closed” position.

- Set the multimeter to the lowest resistance range.

- Place probes on the load terminals.

- A healthy contact should read close to zero ohms.

If resistance is too high, the contacts may be dirty or welded together.

Step 4: Operating Time Test

This test shows how fast the contactor reacts when energized.

- Apply control voltage to the coil.

- Use a stopwatch to measure the closing time.

- De-energize and measure the opening time.

- Compare results with manufacturer values.

Sluggish movement can indicate wear, dirt, or coil failure.

Common Contactor Problems and Fixes

- Fails to Close: This could be due to a loss of control voltage or a faulty coil.

- Chattering Noise: This may be caused by low voltage, worn contacts, or overloaded circuits.

- Stuck Closed: Usually due to welded contacts—replace the unit immediately.

konkluzioni

Testing a contactor doesn’t need to be complicated. With the right tools, a clear process, and basic safety knowledge, anyone can check whether a contactor is healthy or needs replacement. By learning how to test a contactor, you not only extend the life of your electrical system but also keep your equipment safe and reliable.At TOSUNlux, we’ve been manufacturing circuit breakers and electrical equipment for over 30 years. Our mission is to provide safe, practical, and reliable solutions worldwide. To learn more about our products and expertise, visit TOSUNlux.

Tel: +86-577-88671000

Email: ceo@tosun.com

Skype: deri në energji elektrike

Wechat: +86-139 6881 9286

WhatsApp: +86-139 0587 7291

Adresa: Dhoma Nr. 1001 Wenzhou Fortune Center, Station Road, Wenzhou, Kinë

KËRKONI NJË KUOT

Na WhatsApp

: +86-139 0587 7291

: +86-139 0587 7291 anglisht

anglisht Español

Español Русский

Русский Français

Français Arabisht

Arabisht Português në Brazil

Português në Brazil Ukrainas

Ukrainas Türkçe

Türkçe Polski

Polski Hollanda

Hollanda Italiano

Italiano Bahasa Indonesia

Bahasa Indonesia हिन्दी

हिन्दी اردو

اردو አማርኛ

አማርኛ shqip

shqip ไทย

ไทย mongolisht

mongolisht gjuha shqipe

gjuha shqipe Shqip

Shqip English

English