What Is the Difference Between a Terminal Block and a Terminal Strip?

Table of Contents

ToggleThe main difference between a terminal block and a terminal strip is how they are structured. A terminal block is modular and insulated, allowing you to add or remove sections on a DIN rail. A terminal strip, meanwhile, is one fixed row of screw terminals used for simple wire-to-wire connection.

What Is a Terminal Block?

The best way to define terminal block is to see it as a modular connector that secures two or more wires inside an insulated housing. Inside the block, a metal conductor transfers current while a clamping mechanism (screw, spring, or push-in) holds the wire firmly in place. It gives you a safe wiring point without permanent splicing.

What Is a Terminal strip?

A terminal strip is a single fixed row of screw terminals used to connect wires point-to-point. Each section has a metal conductor with a screw on top, allowing the wire to be fastened securely. Unlike a modular terminal block, a terminal strip comes as one long piece and does not mount on a DIN rail. It is mainly used for simple wiring connections where circuits do not need frequent changes.

How Are Terminal Blocks and Terminal Strips Different?

The simplest way to compare terminal strip vs terminal block is by looking at structure, flexibility, and safety. The table below shows how each functions in an electrical setup.

Terminal Block vs Terminal Strip (Quick Comparison)

| Category | Terminal Block | Terminal Strip |

|---|---|---|

| Structure | Modular connector with individual insulated terminals | Single fixed strip with multiple screw terminals in one piece |

| Wiring Flexibility | Can be expanded or reorganized (snap onto DIN rail) | Fixed layout, no modularity |

| Electrical Conduction | Internal metal conductor routes current through each terminal | Screw clamps wire directly to the metal strip (point-to-point) |

| Safety / Insulation | High (each terminal is isolated to prevent shorts) | Basic (wires sit closer together and rely on enclosure for safety) |

| Ideal Use Case | Organized wiring in control panels (automation, power distribution) | Simple junction connections (lighting, appliance wiring) |

Modularity and structure

A terminal block is made of individual units. You can slide them together on a DIN rail and build a clean wiring layout. If a circuit changes later, you can add another block without disturbing the existing wiring.

A terminal strip does not offer this freedom. It is a single long strip. Once installed, the arrangement remains unchanged.

Wiring Flexibility

Terminal blocks mount on a DIN rail. That means you can slide them, rearrange them, or combine different types. This flexibility is one of the main reasons why you need terminal blocks in panels that evolve over time.

A terminal strip does none of this. It stays as a single strip and is used for direct point-to-point wiring. Installers usually choose terminal strips for quick, low-complexity connections.

Electrical Conduction

Inside a terminal block, an internal metal conductor routes electrical current between wires. When you tighten the clamping mechanism, you get a secure, gas-tight connection.

With a terminal strip, the wire is clamped directly to a screw terminal. Power flows straight through the metal strip. It’s simple, direct, and useful for basic circuits.

Safety and insulation

Terminal blocks separate and insulate each connection inside the housing. This prevents accidental contact and reduces the chance of short circuits in high-density panels.

Terminal strips expose more of the metal connection area. They are safe for lower complexity systems but rely on careful installation to avoid contact between wires.

Ideal Use Cases

Terminal blocks are designed for wiring that needs structure and room to expand later. You’ll see them in:

- Control panels and automation systems

- Power distribution cabinets

- Industrial equipment where circuits need labeling and frequent maintenance

- Installations using a busbar connection or DIN rail layout

Terminal strips are better for simple, fixed connections. Common uses include:

- Lighting fixtures and small appliances

- Basic junction boxes

- Audio and low-voltage setups

- Temporary wiring or quick point-to-point connections

TOSUNlux Offers Both Terminal Blocks and Terminal Strips

At TOSUNlux, we offer both terminal blocks and terminal strips. You can use terminal blocks when you need organized wiring inside control panels. Terminal strips work well for simple point-to-point connections. Whether the project requires modular DIN-rail wiring or a quick connection, you can source everything from one place.

TOSUNlux has been in electrical manufacturing since 1994. Our range includes:

- Power distribution components

- Industrial control devices

- New energy and solar protection products

- Electrical accessories, including terminal blocks and terminal strips

Producing under our own brand keeps quality consistent across every component. That means you get accessories, breakers, relays, and wiring hardware that fit together without sizing issues or performance surprises.

Explore our terminal block and terminal strip options.

UK Terminal Block (Modular)

- Modular DIN Rail Mounting

- High-Insulation Housing (PA66)

- Secure Screw Clamp Connection

- Ideal for Control & Distribution Panels

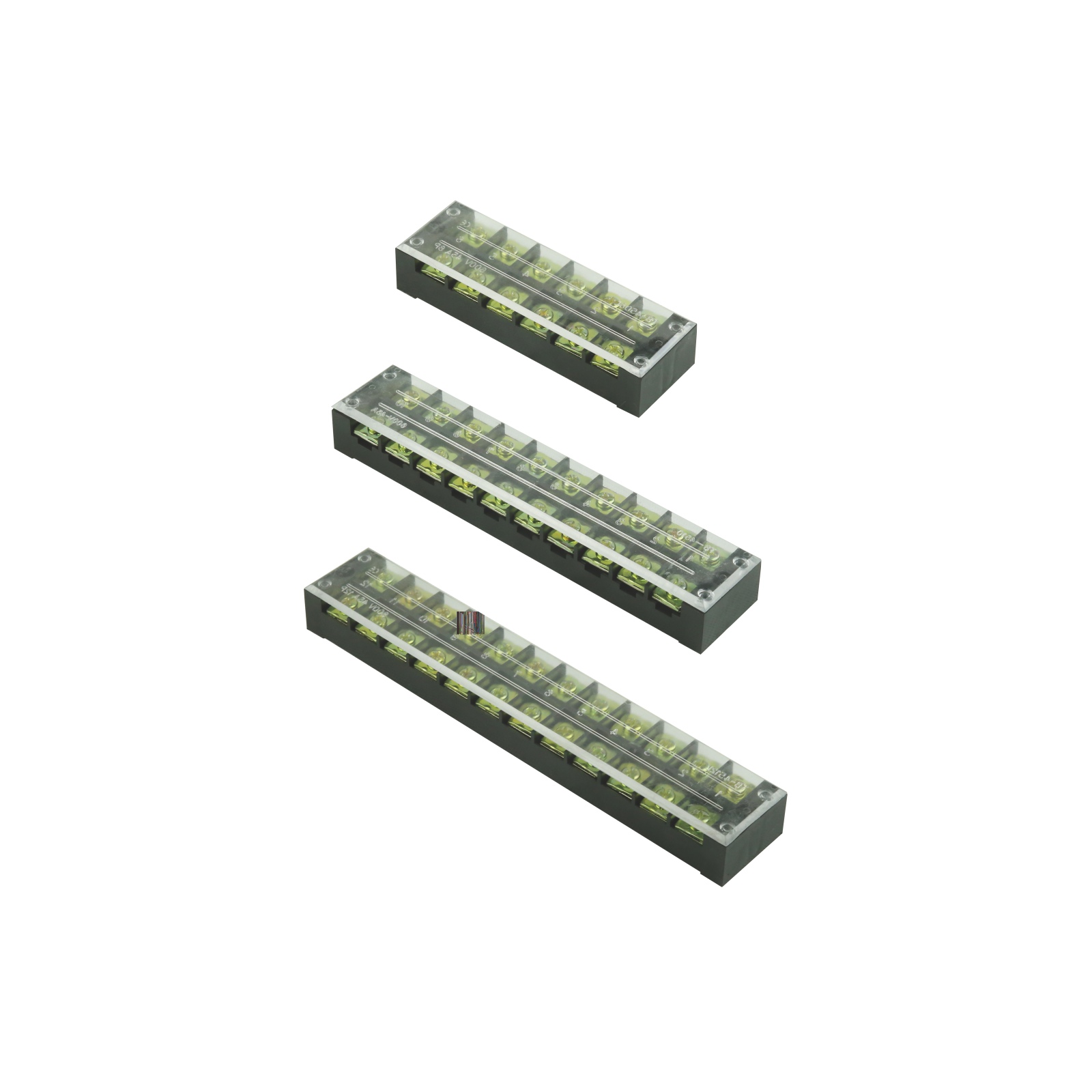

TB TC Terminal Block (Strip)

- Fixed, Single Row Design

- Simple Point-to-Point Connection

- Robust Screw Clamping Mechanism

- Ideal for Basic Appliance Wiring

Final Thoughts

Terminal block vs terminal strip comes down to how much flexibility the wiring needs. If you want structure, labeling, and room to expand later, a terminal block makes the job easier. If all you need is a quick connection point, a terminal strip gets it done.

Looking for a One-Stop LED Lighting Solution?

With 30 years of certified manufacturing, we are the trusted partner for your complete industrial and commercial lighting needs.

FAQ

1. What does a terminal block look like?

A terminal block is usually a small rectangular module with clearly marked wire entry points. It mounts on a DIN rail inside a panel, and each module contains an insulated body with a metal conductor inside. Multiple blocks line up to form a clean wiring row.

2. Why do you need terminal blocks?

You need terminal blocks when wiring requires structure, safety, and room to expand. They keep conductors organized, reduce wiring errors, and make troubleshooting faster since each circuit has its own connection point.

3. Terminal block vs busbar: what’s the difference?

A terminal block connects individual wires and keeps circuits separated. A busbar distributes power to multiple terminals from a single input point.

Think of it like this:

- A terminal block organizes wiring

- A busbar distributes power

4. Are terminal strips reusable?

Yes, terminal strips are reusable as long as the screw terminals and conductor surfaces are in good condition. You can loosen the screw, remove the wire, and reuse the same terminal position in another project.

Tel: +86-577-88671000

E-mail: ceo@tosun.com

Skype: tosunelectric

Wechat: +86-139 6881 9286

WhatsApp: +86-139 0587 7291

Address: Room No.1001 Wenzhou Fortune Center,Station Road, Wenzhou, China

REQUEST A QUOTE

WhatsApp us

: +86-139 0587 7291

: +86-139 0587 7291 English

English Español

Español Русский

Русский Français

Français العربية

العربية Português do Brasil

Português do Brasil Українська

Українська Türkçe

Türkçe Polski

Polski Nederlands

Nederlands Italiano

Italiano Bahasa Indonesia

Bahasa Indonesia हिन्दी

हिन्दी اردو

اردو አማርኛ

አማርኛ Հայերեն

Հայերեն ไทย

ไทย Монгол

Монгол فارسی

فارسی Shqip

Shqip Ελληνικά

Ελληνικά