The Ultimate Guide to 3-Phase Voltage Protectors

08th Jul 2025

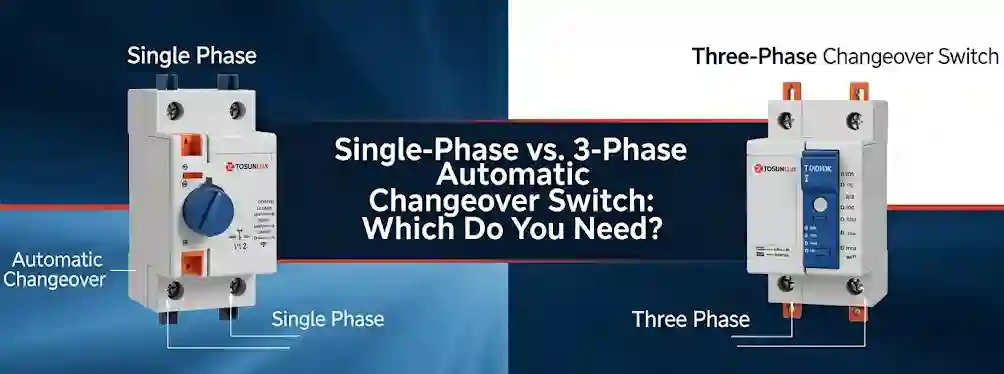

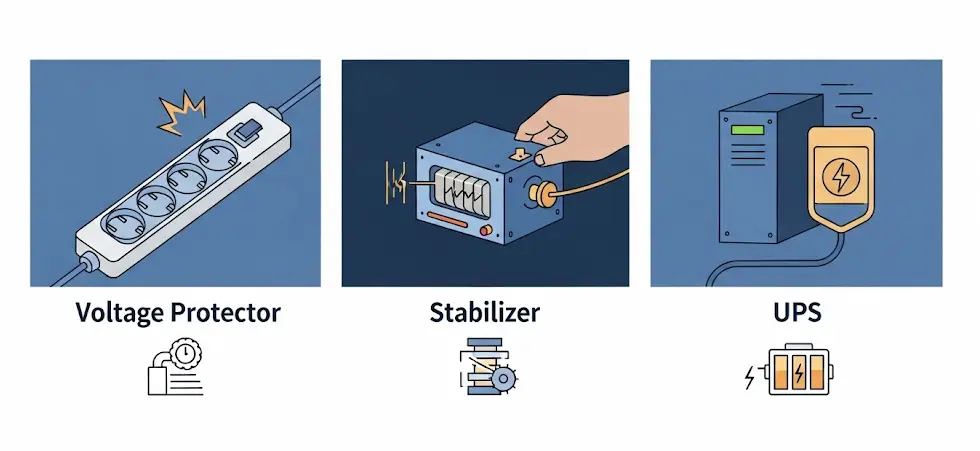

If your operations rely on heavy equipment, motors, or sensitive electronics running on a three-phase supply, then a 3 phase voltage protector is essential. Voltage fluctuations, phase loss, and over-voltage can damage machines, trigger downtime, and ruin critical systems. These protectors are designed to automatically disconnect power when things go wrong and reconnect once everything’s safe again. In this guide, we’ll walk you through how 3-phase voltage protectors work, how they compare to single phase voltage protectors, what to look for, and why a heavy duty over voltage protector can be the difference between smooth operation and costly failure. What Is a 3 Phase Voltage Protector? A 3 phase voltage protector monitors the voltage across all three phases of a power supply. If the voltage becomes too high, too low, or if any of the three phases becomes unbalanced or fails completely, the device will automatically disconnect the power supply to prevent damage. Once voltage levels return to normal, it reconnects power—automatically and safely. This is different from a single phase voltage protector, which monitors only one live and one neutral line. Single-phase units are common in homes and small offices. But in factories, data centers, and large buildings where power demand is higher, three-phase systems are the standard—and so is three-phase protection. Why It Matters in Real Operations Three-phase systems power large motors, elevators, cooling units, and production lines. These setups are more efficient for high-load operations, but they’re also more vulnerable to: A three phase voltage protector constantly checks each line and reacts […]

Read More : +86-139 0587 7291

: +86-139 0587 7291 English

English Español

Español Русский

Русский Français

Français العربية

العربية Português do Brasil

Português do Brasil Українська

Українська Türkçe

Türkçe Polski

Polski Nederlands

Nederlands Italiano

Italiano Bahasa Indonesia

Bahasa Indonesia हिन्दी

हिन्दी اردو

اردو አማርኛ

አማርኛ Հայերեն

Հայերեն ไทย

ไทย Монгол

Монгол فارسی

فارسی Shqip

Shqip Ελληνικά

Ελληνικά