How to Select Suitable DC Breakers ?

25th Mar 2025

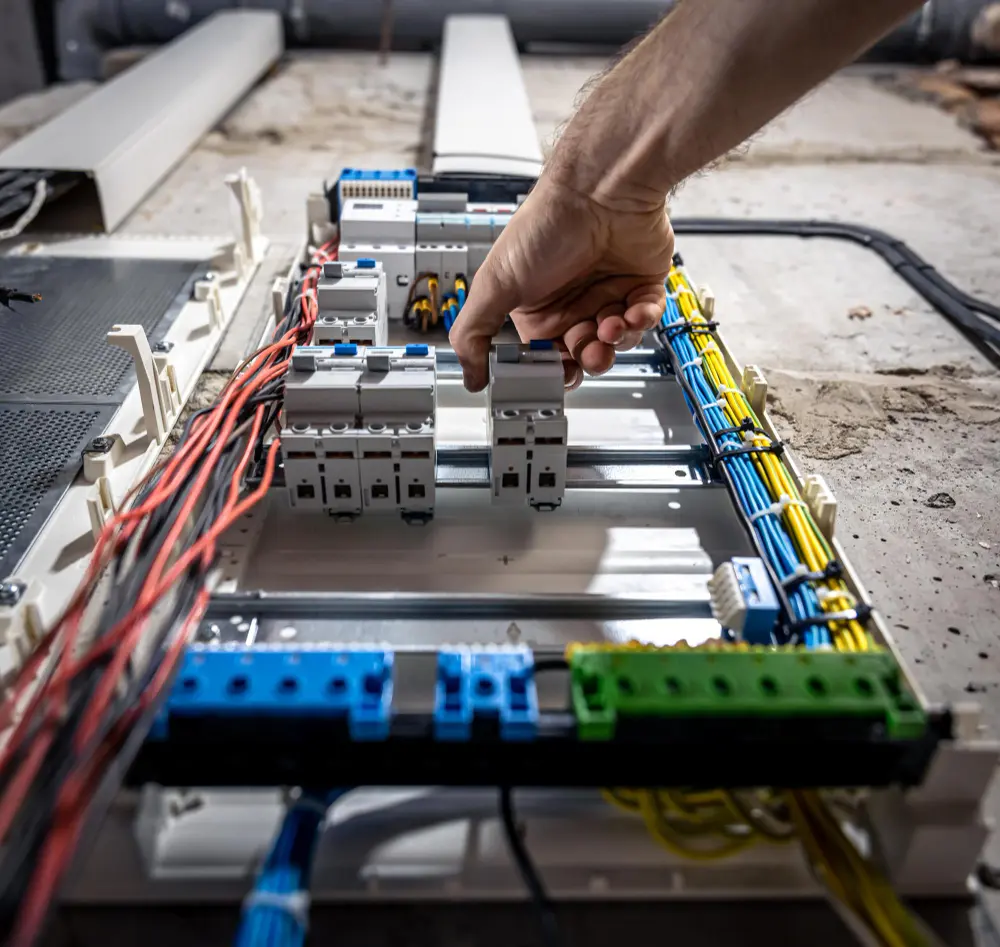

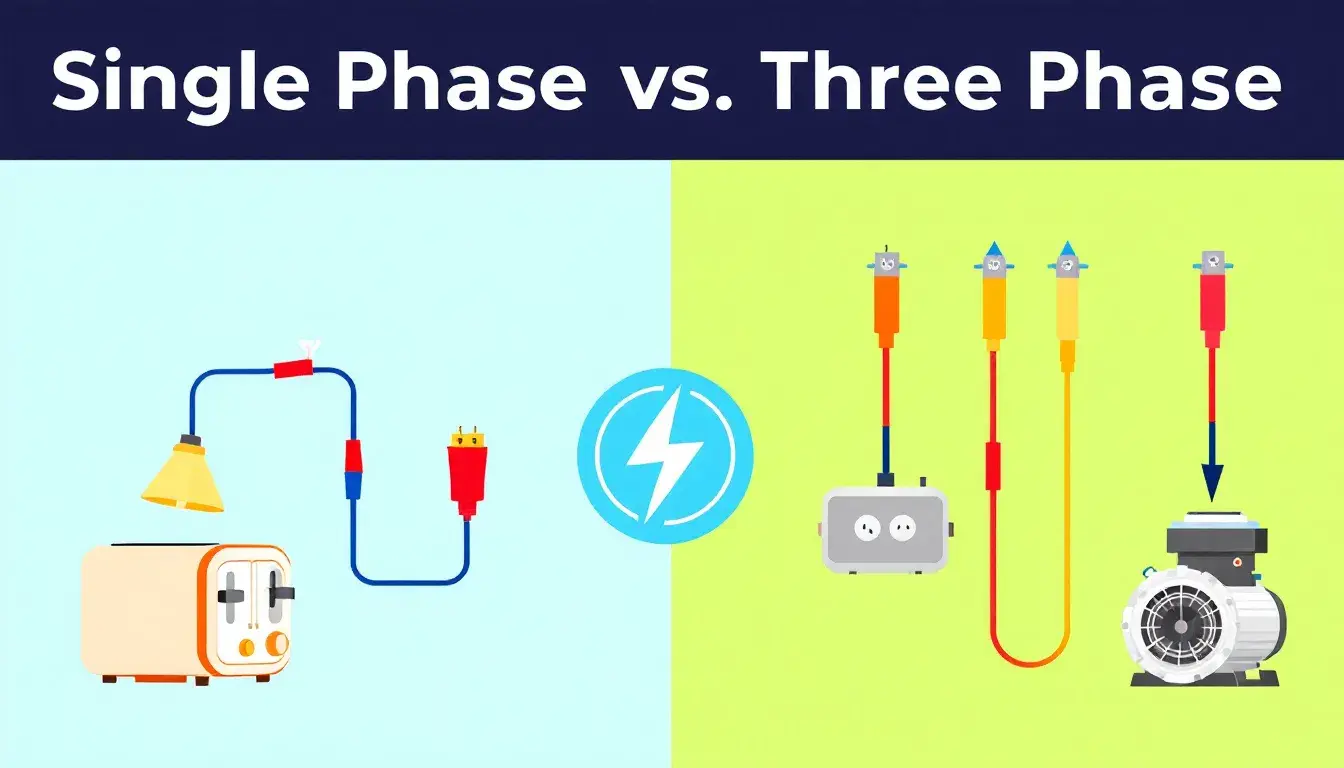

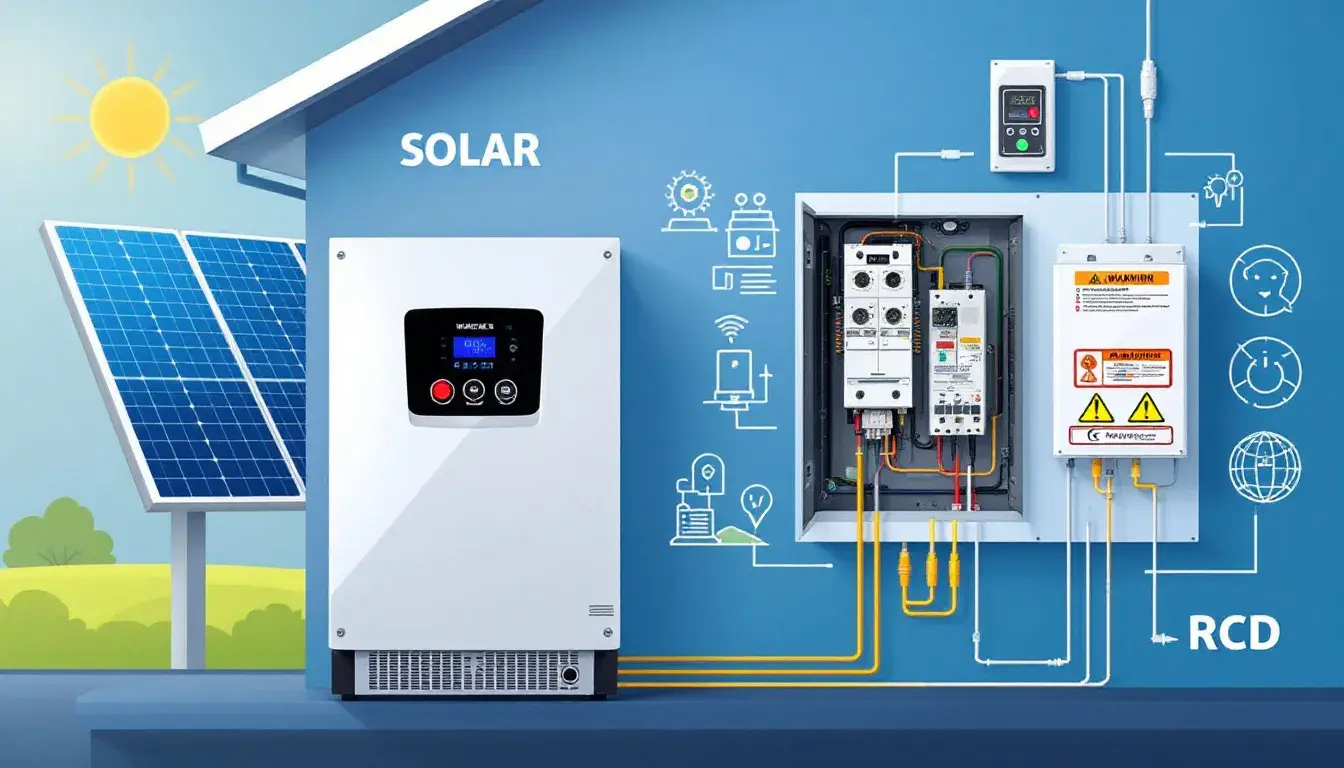

Did you know that selecting the right DC circuit breaker can prevent up to 80% of electrical mishaps in your home or business? In this article, we delve into the world of DC breakers, essential for safeguarding your electrical systems. You’ll learn about the different types of DC circuit breakers, their key features, and why proper sizing is crucial. We will guide you through the factors to consider when choosing a breaker, including ambient temperature and load capacity. Whether you’re a homeowner or an industry professional, this guide will equip you with the knowledge to make informed decisions, ensuring safety and efficiency in your electrical installations. Read on to become an expert in selecting suitable DC breakers! What is a DC Circuit Breaker? A DC MCB, or Direct Current Miniature Circuit Breaker, is a small device that helps protect electrical circuits. As a type of circuit breaker, it works by stopping the flow of electricity when the current gets too high, preventing damage to appliances and reducing the risk of electrical fires. Circuit breakers also help prevent electric shock, ensuring system safety and protection. Key Features of DC MCBs: Rated Current: This is the maximum current the MCB can handle safely. For example, a DC MCB with a rated current of 20 amps can manage up to 20 amps without tripping. The rated current is specified at a certain ambient temperature, and performance can vary if the MCB operates outside of this temperature range. Breaking Capacity: This refers to the highest current the MCB can […]

Read More : +86-139 0587 7291

: +86-139 0587 7291 English

English Español

Español Русский

Русский Français

Français العربية

العربية Português do Brasil

Português do Brasil Українська

Українська Türkçe

Türkçe Polski

Polski Nederlands

Nederlands Italiano

Italiano Bahasa Indonesia

Bahasa Indonesia हिन्दी

हिन्दी اردو

اردو አማርኛ

አማርኛ Հայերեն

Հայերեն ไทย

ไทย Монгол

Монгол فارسی

فارسی Shqip

Shqip Ελληνικά

Ελληνικά