Difference Between Double Pole and Single Pole Breaker: Simplified

11th Feb 2025

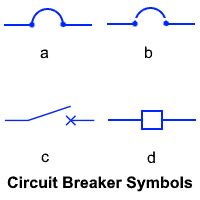

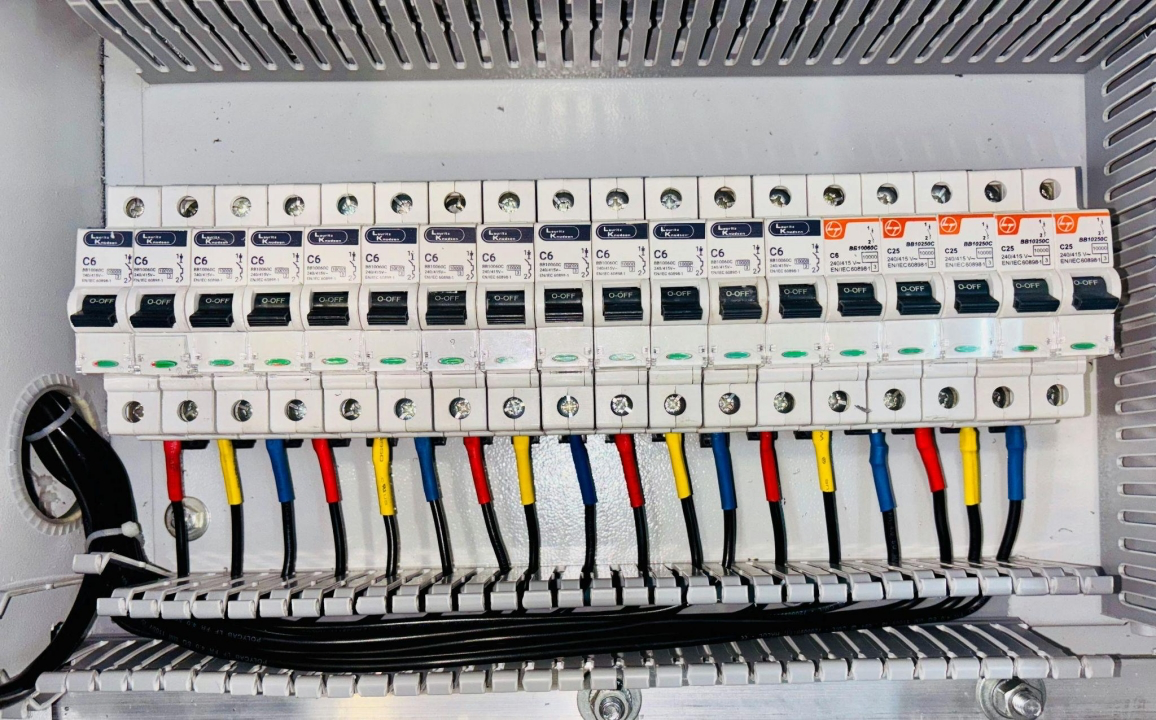

The key difference between a double pole and a single pole breaker is that a single pole breaker controls one 120V circuit, while a double pole breaker controls a 240V circuit by connecting to two hot wires. Double pole breakers handle more power and are used for larger appliances, while single pole breakers are used for standard household outlets and lights. Read on to learn more. Single Pole vs Double Pole Breaker: Quick Comparison Table Feature Single Pole Breaker Double Pole Breaker Voltage Rating 120V 240V Number of Hot Wires 1 2 Amp Rating Commonly 15-20A Commonly 20-50A Usage Lights, outlets Water heaters, dryers, HVAC units Breaker Width 1 slot in the panel 2 slots in the panel Trip Mechanism Trips when one wire overloads Trips when either wire overloads How Does a Single Pole Breaker Work? A single pole breaker is a circuit breaker that connects to one hot wire and one neutral wire, delivering 120V power. It trips when there is an overload or short circuit, cutting off power to the affected circuit. These breakers are commonly rated at 15 to 20 amps and are used for standard home electrical outlets, lighting, and small appliances. Common Applications of Single Pole Breakers Indoor and outdoor lighting circuits Standard electrical outlets in living rooms and bedrooms Small appliances like TVs, coffee makers, and microwaves 120V circuit breakers in home electrical panels How Does a Double Pole Breaker Work? A double pole breaker connects to two hot wires, providing 240V power. It trips when there is […]

Read More : +86-139 0587 7291

: +86-139 0587 7291 English

English Español

Español Русский

Русский Français

Français العربية

العربية Português do Brasil

Português do Brasil Українська

Українська Türkçe

Türkçe Polski

Polski Nederlands

Nederlands Italiano

Italiano Bahasa Indonesia

Bahasa Indonesia हिन्दी

हिन्दी اردو

اردو አማርኛ

አማርኛ Հայերեն

Հայերեն ไทย

ไทย Монгол

Монгол فارسی

فارسی Shqip

Shqip Ελληνικά

Ελληνικά